Craftsmanship

of

Japan

The Home of Craftsmanship

Shoes from THE ONITSUKA and NIPPON MADE series are made at OnitsukaTiger’s in-house factory. Imbued within these products is the aesthetic ofJapanese craftsmanship—spun by the skilled hands and heartfelt dedicationof our artisans.

The making of THE ONITSUKABROGUE: First, the upper parts arecut. A die is placed on top of theleather, and a cutting machineapplies pressure and pulls the partout. The delicate perforations, orbroguing, are embedded in thedie, and the process requi resconsiderable ski l l to executeprecisely.

-

Cutting the soles. The shelvesare lined with sole dies organized bysize. -

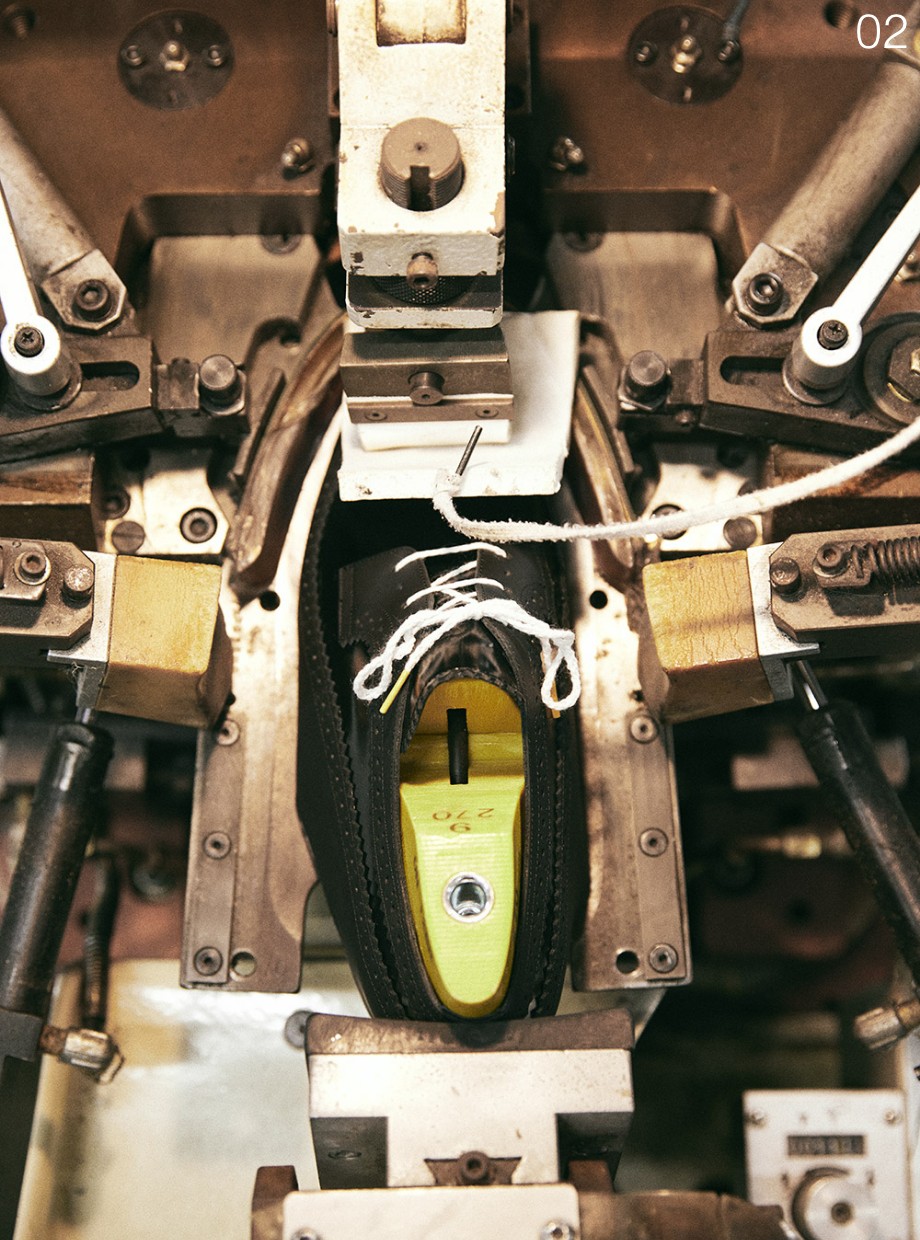

A process called lasting, wherethe sewn uppers are shaped to fit thefoot molds. The forefoot portion isinitially done by machine. -

The side lasting is performedby hand. It takes skilled artisans to makethe stiff leather of THE ONITSUKAconform to the last.

Onitsuka Tiger’s in-house factory serves asour main production site in Japan—that is,the shoes produced here showcaseJapanese craftsmanship around the world.Typically, our overseas factories focus ononly one or two models on the productionline to increase output. Our productiondepartment representative at the Japan siteexplains.

“Overseas, if we have fifty processes inoperation, fifty workers will each handle onlyone process, with another worker inspectingtheir work. But in our kind of high-mix, smallbatchproduction the available workforce islimited. So it’s crucial that each person takesresponsibility for their work and makesprecise judgments before passing over forthe next step. Each worker acts as their owninspector, doing everything they can beforehanding on to the next person. Ultimately, itcomes down to the gradual accumulation ofthese individual efforts.”

Across the world, our factory’s ability tomanufacture both dress shoes like THEONITSUKA BROGUE and sneakers on thesame production line is unparalleled.

-

When bonding the uppers and soles, a polishingprocess called buffing is performed to increaseadhesive strength. Delicate craftmanship is essential tocreate a uniform surface. -

After buffing is complete, adhesive is applied. -

The adhesive is evenly applied to the upperto prevent distortion. The type of adhesive useddepends on the materials being bonded. -

After manually adhering the uppers andsoles, they are secured and bonded using a press. -

Inserting the insoles into themolded shoes and threading thelaces. The artisan expertly threadsthe laces while ensuring there areno problems with the product. -

A freshlyfinished THEONITSUKA BROGUE. Each pairundergoes thorough inspectionbefore being packaged and shippedworldwide.

While Onitsuka Tiger’s history of manufacturingbusiness shoes acts as a foundation, it is theattitude and spirit of each and every artisanthat makes it all possible.

Cut parts are sewnto create the uppers, which are shaped over awooden last and bonded to the soles. Thoughthe process sounds simple, for each modeland material the techniques and necessaryforce differ subtly but significantly. The abilityto respond to these variations with flexibilityand meticulous care is a testament not only toJapanese humility and dedication, but also tothe artisans’ unparalleled craftsmanship.

“Here, our employees remember every itemthey’ve made. The joy of meeting someonewearing their shoes and the desire to createsomething wonderful for them—that’severything,” our representative adds.

Kihachiro Onitsuka visited this factory everyyear, sharing his passionate commitment forcraftmanship with employees. Our artisanscontinue to work with humility and diligence tothis day, taking pride in what is NIPPON MADE.